RUSS NAYLOR

Co-Founder

[email protected]

Russ Naylor has over 30 years of experience as a licensed architect and contractor.

After graduating with a Masters in Architecture from UCLA, Russ began his career in Los Angeles before moving to San Francisco to work first with Skidmore, Owings & Merrill and then Ai+Architecture.

As a talented and driven architect, Russ became a partner at architecture firm NC2 Studio, where he focused on designing large-scale and mixed-use commercial, retail and multi-residential projects. His designs continue to shape the city’s skyline today.

Russ is now a founding partner at BŌK Modern, where he leads the industry in reimagining architectural metal systems. At BŌK, Russ focuses his skills on design and product development and continues to revolutionize the field.

As an inventor and problem solver, Russ’s design approach is steeped in a realistic understanding of the key components of the development process. This realistic understanding, combined with his creative flair, has allowed him to create groundbreaking products that are both practical and beautiful.

HEDDIE CHU

Heddie Chu has over 20 years of experience managing and operating design firms and institutions both domestically and internationally.

Heddie began to feed her passion for design at the Parsons School of Design and New York University, where she studied fashion design and communication design in both New York City and Paris.

After her studies, she began her career in New York City where she flourished as a designer. Heddie quickly rose to prominence as a designer and an art director for a number of high-profile companies, including fashion designer Giorgio Armani, the Martha Stewart LIVING magazine and advertising firm J. Walter Thompson. She has been a professor of Communication Design at the Parsons School of Design and the California College of the Arts.

During her time at the Parsons School of Design, where she received her BFA, Heddie established affiliate schools in South Korea and Malaysia, leading the development of their design curriculum and creating the operations infrastructure for the school in those countries.

As a partner of architecture firm NC2 Studio, Heddie skillfully led the interior design division and managed business development and operations.

Today, as a founding partner of BŌK Modern, Heddie drives business development and operations with sophistication and efficiency.

BŌK Modern can provide a simulation of our pattern on your project through advanced 3D renderings.

Submit the form below for more information on pricing and lead-times:

Every project begins with a vision and we are passionate about making your vision a reality.

At BŌK Modern, we pride ourselves on our proven track record of skillfully designing and fabricating custom projects with our clients – we have done everything from standard to complex. Our ability as creative problem solvers is unmatched in the field.

Through our Design Support process, our diverse team of experts, with their combined knowledge in multiple fields, will work diligently to identify pitfalls before progress stagnates.

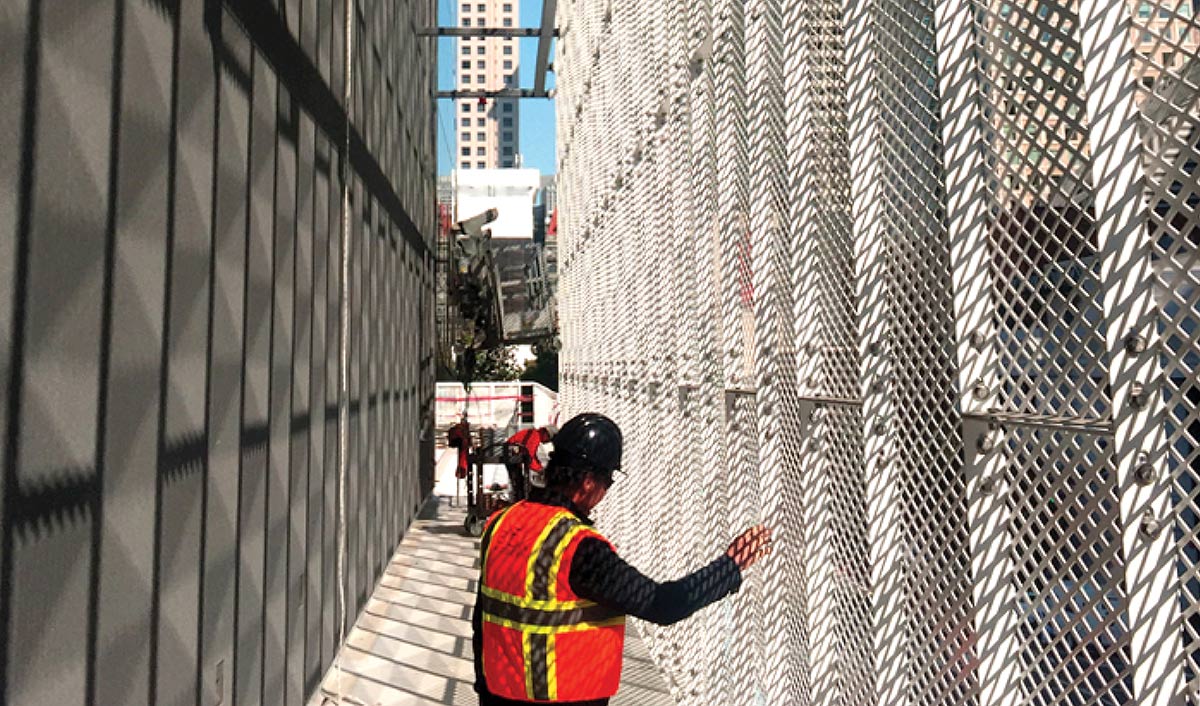

Headed by Russ Naylor, who has been making his mark on San Francisco’s skyline for decades, our dedicated Design Team is comprised of product designers, engineers, and architects. Together, we have many years of expertise and knowledge upon which to draw.

During our Design Support collaboration process, our Design Team will work with the architect, installers, GC’s and engineer of record to conduct a pre-assessment of the engineering for each project. We are often able to identify and remove unnecessary support substructures and to suggest novel applications for our modular systems.

With your help, we are able to seamlessly streamline construction and improve both buildability and sustainability. This process allows BŌK to provide a more accurate estimate of final costs compared to a typical ROM estimate and result in considerable cost savings when compared to conventional construction methods.

Our design approach is steeped in a realistic understanding of the key components of the development process. By getting involved early, our goal is to make installation as simple and efficient as possible and to fine tune the project budget so that a reliable and accurate cost for your clients. We are able to achieve all of this while respecting and preserving the integrity of your design intent.

We offer this service at no charge for simpler projects. For more complex projects, we provide a Design Contract to formalize this process and provide a firm cost for your client. Our Design Team is available to collaborate with you every step of the way. Any costs for this service will be credited back to your project once it becomes active.

From aspiration to inspiration to reality, we will be there every step of the way.

LEARN MORE BY CALLING 415-749-6500 x 295 OR SENDING US AN EMAIL.

TERMS & CONDITIONS:

Please register here to view the BŌK Modern Standardized Details in PDF.

If you’d like a specific CAD format drawing, please contact BŌK at 415.749.6500.

You must be registered to receive any BŌK Modern CAD file.

COPYRIGHT NOTICE: All designs and drawings shown on this website are the intellectual property of BŌK Modern LLC (“BŌK Modern”), are protected by international copyright and/or patent law and may not be copied or reproduced without the express prior written permission of BŌK Modern. Reproduction of these designs or drawings, either in whole or in part, including any form of copying or preparation of derivative works thereof, for any reason, without BŌK Modern’s prior written permission, is strictly prohibited. BŌK Modern takes its intellectual property rights very seriously and prosecutes infringement to the fullest extent of the law.

© 2024 BŌK Modern LLC. All rights reserved.

Heddie has 20 years of experience working with national and international design firms and design institutions. Her experience enables her to lead Naylor & Chu with operational sophistication and efficiency.

Heddie began her career in New York City as a designer and an art director for several prominent companies including Georgio Armani, Martha Stewart LIVING Magazine, and J. Walter Thompson Advertising.

Internationally, Heddie found sponsors and investors to establish affiliate schools for the Parsons School Of Design New York in South Korea and in Malaysia. She lead the operations and marketing side of the program.

Heddie’s passion for the design business supports her leadership in developing comprehensive business, marketing and operations plans, as well as utilizing her network skills to create the right support for the projects and Naylor & Chu.