Cost effective projects make the most practical use of raw material sheet sizes. Configuring panel sizes that include face and edge forming to fit standard sheet sizes while satisfying engineering requirements can avoid excess waste.

Standardizing panel types as much as possible can save on design and documentation time. More units of fewer types drives cost down. Use a standard pattern and panel repeat vs. a continuous custom pattern image with many one-off panels. Each change in panel type, face size, variation in pattern, or edge detailing creates added panel types resulting in added costs.

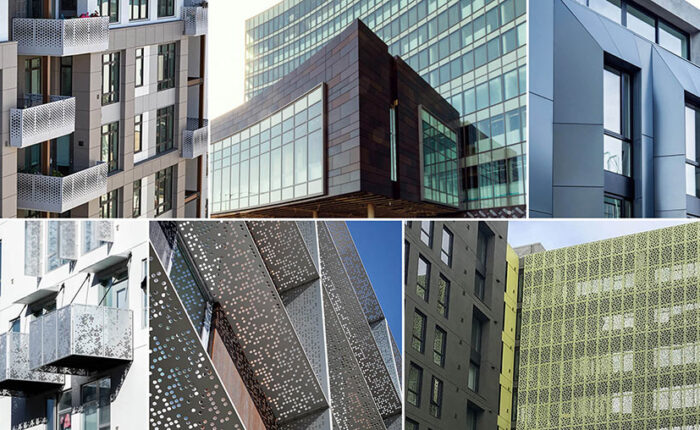

Simple geometric shapes and moderately sized openings are more efficient to cut. Please see pattern library for our standardized patterns or contact BŌK Modern to talk you through guidelines for designing a custom, cost effective pattern.

HEDDIE CHU

HEDDIE CHU